Enhancing energy efficiency in the refinery and petrochemical sector

Enhancing energy efficiency in the refinery and petrochemical sector

Centrifugal compressors and reboilers are crucial in refineries and petrochemical plants, accounting for up to 50% of energy use. Their efficiency depends on maximising latent heat extraction during steam condensation and maintaining proper pressure and temperature in condensers.

With over 75 years of water treatment expertise, Kurita’s patented Dropwise Condensation Technology is trusted by more than 500 customers worldwide to improve productivity and boost heat transfer efficiency in steam condensation systems.

Why Choose Kurita Dropwise Condensation Technology?

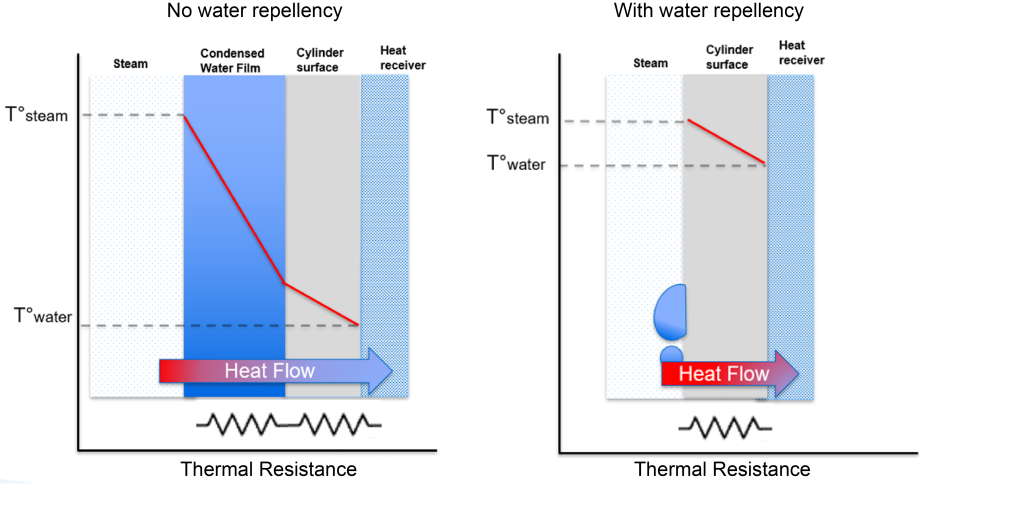

Kurita’s solution enhances steam condensation efficiency in the petrochemical industry by eliminating the condensate layer and improving heat transfer.

+30% Higher Heat Transfer Efficiency

Our advanced solution eliminates the condensate layer barrier, dramatically increasing heat flow and system performance.

Significant Energy & Cost Savings

+16% power production and compression capacity in steam-driven turbines and compressors, plus + 8% steam savings in distillation column reboilers.

Vacuum Level Reduction

Lower vacuum levels in steam condensers for improved operational stability

Lower Carbon Emissions

Reduced steam and fuel consumption directly translates to lower CO₂ emissions, helping you meet environmental targets.

No Major CAPEX Required

Kurita Dropwise Condensation Technology is easily integrated into existing steam lines with minimal investment.

Award-Winning Innovation

Recipient of the Energy Conservation Grand Prize for improved heat transfer efficiency.

How It Works

Kurita Dropwise is continuously dosed into the steam line, forming a hydrophobic monomolecular film on condensation surfaces. This film prevents water from creating an insulating layer, enabling dropwise condensation and superior heat transfer. The system is compatible with all conventional boiler water treatments and does not affect condensate water quality.

Seamless Implementation & Support:

-

Expert Installation

Local Kurita specialists tailor dosing and installation for each plant, ensuring maximum efficiency.

-

Continuous Monitoring

The Kurita Way model focuses on providing personalized service. A local Kurita manager will regularly visit the plant, adjust treatments, monitor KPIs and water quality, and address customer inquiries.

-

Evaluation

Kurita Connect 360 provide real-time monitoring, analytics, and reporting for full visibility and control.

Testimonials

Additionally, the steam condensate containing this chemical can be returned to the system as boiler feed water.

- Condensing turbine has maintained condenser vacuum levels despite rising seawater temperatures from 2021 to 2023, particularly in summer. This improvement resulted in over a 10% increase in gas compressor output.

- Steam condensate with Dropwise additive (15-20 mg/L) can be reused as boiler feed water.

- Technical assistance remains timely and relevant.

Additionally, the technical assistance provided has been timely and relevant.

Case Studies

Improvement of heat transfer coefficient in Ammonia Recovery Reboiler Unit

Boosting heat transfer efficiency of the condenser and increased the heat drop of the steam turbine

Operation Improvement by Increasing Heat Transfer in Boiler Condenser

Related Solutions

S.sensing™ VP

Kurita’s S.sensing™ VP concept smartly monitors water treatment systems, offers insights, identifies areas for improvement, and helps reduce energy use to achieve sustainability goals.

Kurita Dropwise Technology

Kurita Dropwise Technology revolutionizes heat transfer efficiency by applying a unique surface treatment that enables dropwise condensation. This innovative approach reduces energy consumption, improves operational reliability, and supports sustainable performance in industrial processes

Kurita Connect 360

Kurita’s digital customer platform for global water management enhances your system performance by providing continuous intelligent recommendations and monitoring of your water treatment applications.