Manažer pro ocelářství a těžební průmysl

Ocelářský průmysl se v současné době potýká s řadou problémů - někdy s jedním, jindy se všemi najednou. Kontrola rozptýlených emisí spadá do druhé kategorie.

Regulace prašnosti se stala hlavním cílem a účinným nástrojem pro snižování emisí pevných částic (PM), a to od skladů surovin až po aglomerační a koksárenské pece.

Důvody jsou různé. Klíčovým faktorem je samozřejmě odpovědnost za životní prostředí, která však jde ruku v ruce s vytvářením pracoviště bez rizik, dodržováním regulačních norem, dosahováním cílů udržitelného rozvoje pro zúčastněné strany a prostým udržováním dobrých vztahů se sousedními komunitami v okolí ocelárny.

Zatímco usměrněné emise lze řídit pomocí osvědčených technologií, jako jsou odprášení a mokré pračky, rozptýlené emise představují větší problém kvůli své nepředvídatelné povaze. Ano - jsou rozptýlené a faktorů ovlivňujících vznik prachu je mnoho.

Při hodnocení zdrojů prachu v budově obvykle přicházejí v úvahu tři hlavní oblasti ocelárna:

- Sběrné dvory surovin

- Spékací závody

- Koksovny

Každá z těchto oblastí má společná bolestivá místa:

- Zásoby

- Pásové dopravníkové systémy

- Nezpevněné cesty

Zásoby jsou hlavním zdrojem emisí prachu. Často se nacházejí ve větrných oblastech, jako jsou přístavy, a představují velké plochy náchylné k erozi. To vede k prašnosti v surovinových skladech a ztrátám materiálu, což může mít přímý dopad na výrobní náklady.

Ke zmírnění těchto účinků používají výrobci vodné roztoky s krustami, které se rozprašují na zásoby a vytvářejí ztuhlou vrstvu odolnou proti větrné erozi.

Takže - snadná oprava? Jen částečně.

Sběrné surovinové dvory jsou rušným prostředím. Řízení zásob je umění samo o sobě. Kdykoli mohou přijet lodě, nákladní auta nebo vlaky, které vykládají a vytvářejí nové hromady. Při této neustálé činnosti je třeba stále provádět kontrolu prašnosti.

Z dálky je kůra vytvořená běžným ošetřením sotva viditelná. Praktickým řešením je použití prostředků na tvorbu krust v různých barvách - jako např. Ferrosolf® v bílé nebo zelené barvě - umožňuje snadnou vizuální identifikaci ošetřených hromádek, posouzení pokrytí kůrou a plánování budoucích ošetření.

Nezpevněné cesty jsou dalším zdrojem prachu, zejména při používání těžkých strojů. V závislosti na meteorologických podmínkách se používají buď prostředky vytvářející krustu, nebo hygroskopické materiály. Zatímco krusty mají tendenci se časem rozpadat, hygroskopické materiály vytvářejí smáčecí efekt, který zabraňuje tvorbě prachu. Společnost Kurita tento přístup zdokonalila tím, že vyvinula výrobek, který kombinuje tvorbu krusty a účinky smáčení, s ekologickou stopou.

Pásové dopravníkové systémy představují jedinečné výzvy, zejména při přepravě horkých materiálů, jako je aglomerát nebo koks. Zde se používají dvě hlavní metody omezování prašnosti: mokrý postřik a systémy na bázi pěny.

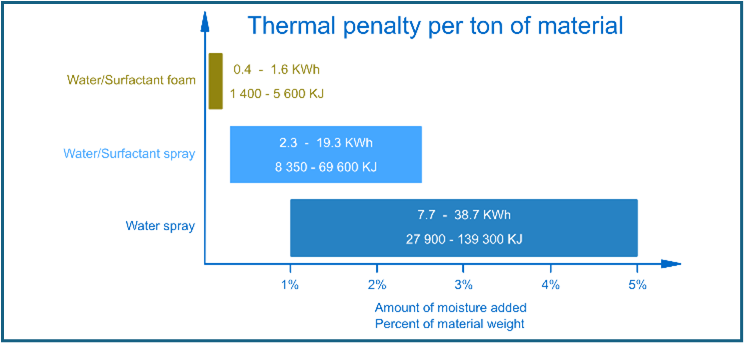

Systémy mokrého postřiku mohou být účinné díky chladicímu účinku, ale také vnášejí do materiálu vlhkost. Tato vlhkost se musí odpařit v následných procesech (např. ve vysokých pecích nebo koksárnách), což vede k tepelným ztrátám a zvýšení celkových nákladů na vlastnictví (TCO).

Pěnové systémy, které dodávají relativně "suchou" pěnu pomocí stlačeného vzduchu a specializovaných trysek, mohou dosáhnout podobného snížení prašnosti při minimalizaci spotřeby vody - až na 0,1% (1000 ppm). Pěnové jednotky jsou ideální v případech, kdy proces nebo materiál nesnese nadměrnou vlhkost nebo kdy je rozhodující minimalizovat energetické ztráty. Pro tyto účely používá společnost Kurita svůj patentovaný FFE® Systém, která je vybavena automatickou jednotkou pro tvorbu pěny a kontrolu prašnosti.