Senior Product Manager Process Chemicals

Challenges to industry for a greener future

Nowadays, it is impossible to imagine our daily lives without products that contain metals or plastic materials, such as computers, televisions, kitchen and household appliances, mobile phones or vehicles with which we can easily reach other places. The production of these goods requires energy and pollutes the environment. Until a few years ago, often no major efforts were made to reduce emissions because the energy costs for electricity or gas were low.

This situation has now changed fundamentally worldwide and manufacturing companies are looking for ways and solutions to keep the demand for energy during production as low as possible. Emissions should be avoided as far as possible or at least kept as low as possible in order to continue to provide future generations with an environment and future worth living in.

Carbon footprint

The carbon footprint is a measure of the total amount of carbon dioxide emissions that occur directly or indirectly during production. In the meantime, the term “carbon footprint” is on everyone’s lips and has gained a lot of importance in recent years. Customers ask about the CO2 footprint of commercial goods and production companies are evaluated accordingly. If one can permanently reduce the energy demand and CO2 balance, this helps the environment and at the same time provides the producing company with a long-term production advantage.

Fouling control

During production, unintentional deposits can contaminate important plant components and lead to production losses. The deposits cannot always be removed quickly, which sometimes requires extensive cleaning measures.

There are many types of deposits that unintentionally degrade production performance. Common causes are, for example:

- Deposits of corrosion products

- Agglomeration of compounds containing hydrocarbons

- Salt deposits that are difficult to remove even with washing water

Fouling can often be prevented or at least significantly reduced by selecting a suitable antifoulant programme. This extends the runtime of the process unit and less energy is required for heating power, which at the same time leads to lower emissions.

What is ACF Technology?

Kurita’s ACF Technology is used when strong acids (e.g. hydrochloric acid) or their ammonium salts attack the metal surface of distillation equipment.

ACF additives contain a very strong organic base that immediately reacts with the acids to form a liquid ACF salt to prevent further corrosion. Already formed and deposited ammonium salts, which are observed in many oil refineries, are dissolved and removed with the product stream by forming liquid ACF salts.

Compared to strong acids and their ammonium salts, ACF salts have a neutral pH value and a very low corrosion potential. This prevents further corrosion by acid attack or salt deposits.

Apply ACF Technology and get rid of salt fouling with energy savings

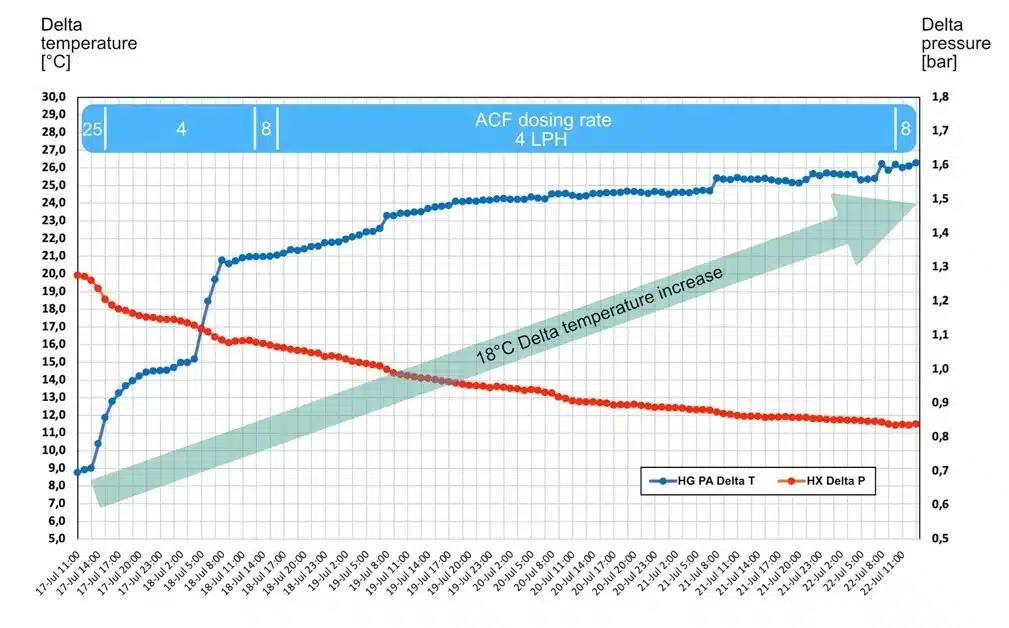

The next example shows how quickly salt deposits present in an FCC main fractionator column can be dissolved during a trial phase, causing the differential pressure in the column to drop significantly and the differential temperature to rise again. Less heating energy is required to ensure optimal process conditions and water washing, which would have a negative impact on production, is not necessary.

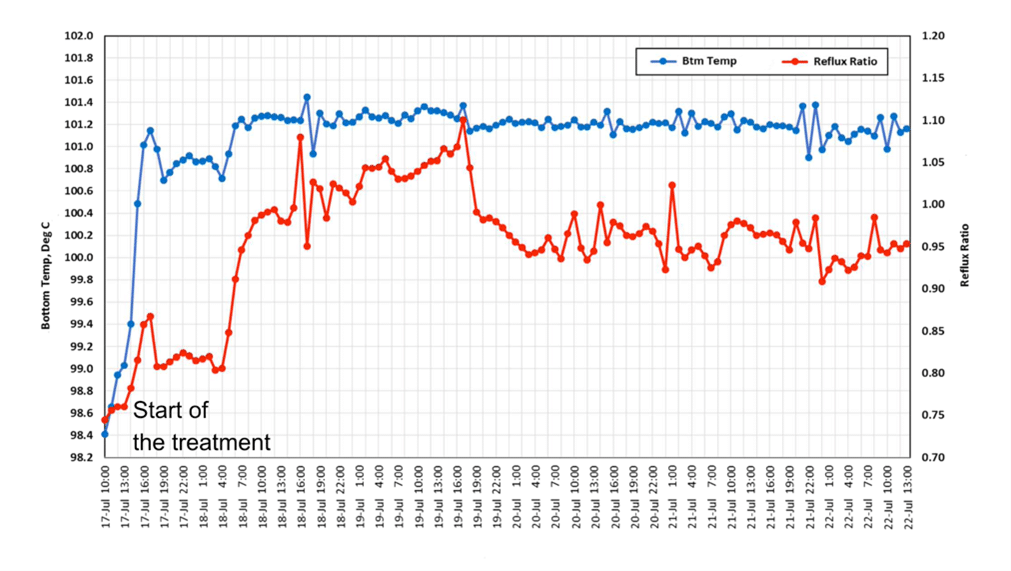

During the online cleaning of the FCC main fractionator column, it was noticed at the same time in the associated depropanizer column, that the use of the ACF additive also had positive effects there. The temperature in the bottom section rose quickly, which meant that less heating energy was needed there as well, resulting in a better CO2 balance.