At Kurita, we create shared value with customers and the environment. That’s why we developed our Value+ product portfolio, which aims to enhance productivity while reducing the total cost of operations (TCO) and supporting sustainability goals.

Our range of technologies, products, and services effectively minimizes water, waste, and energy consumption while also lowering carbon emissions.

Economical Savings for your Boiling System

Kurita’s comprehensive Cetamine® Technology provides excellent protection against corrosion in boiler systems. Composed of film-forming substances, Cetamine creates a hydrophobic protective film acting as a barrier between water and metal, effectively inhibiting corrosion and scaling.

As an all-organic treatment program, Cetamine® allows optimized blow-down rates with higher cycles of concentration leading to significant lower fresh make-up water consumption, savings in energy and reduction of CO2 emission

Applications

- Low To High Pressure Systems

- High Pressure (Turbines)

- Food Industry (Direct Food Contact)

- Discontinuous Boiler Operation (Power Plants)

- Alkaline Boiling-Out

- Wet And Dry Preservation

Cetamine® Technology Features and Benefits

Efficiency

- Clean system surfaces

- Better heat transfer & boiler efficiency

- Higher cycles of concentration

Savings

- Reduced water & energy consumption

- Economical savings

Easy Handling And Control

- 1 product instead of 3

- Flow-meter controlled dosing proportional to make-up water

- Online monitoring & dose rate control

Protection

- Exceptional protection against corrosion & scaling throughout whole water/steam system

- Long term protection during discontinuous operation and system shut-down

Environment Impact

- Reduced blow-down and water discharge

- Reduced CO2 emission

Food Safety

- Complies with international food regulations

Cetamine® Savings Calculator

Predicted Savings with Cetamine in your Boiler System.

Monitoring and Digital Control

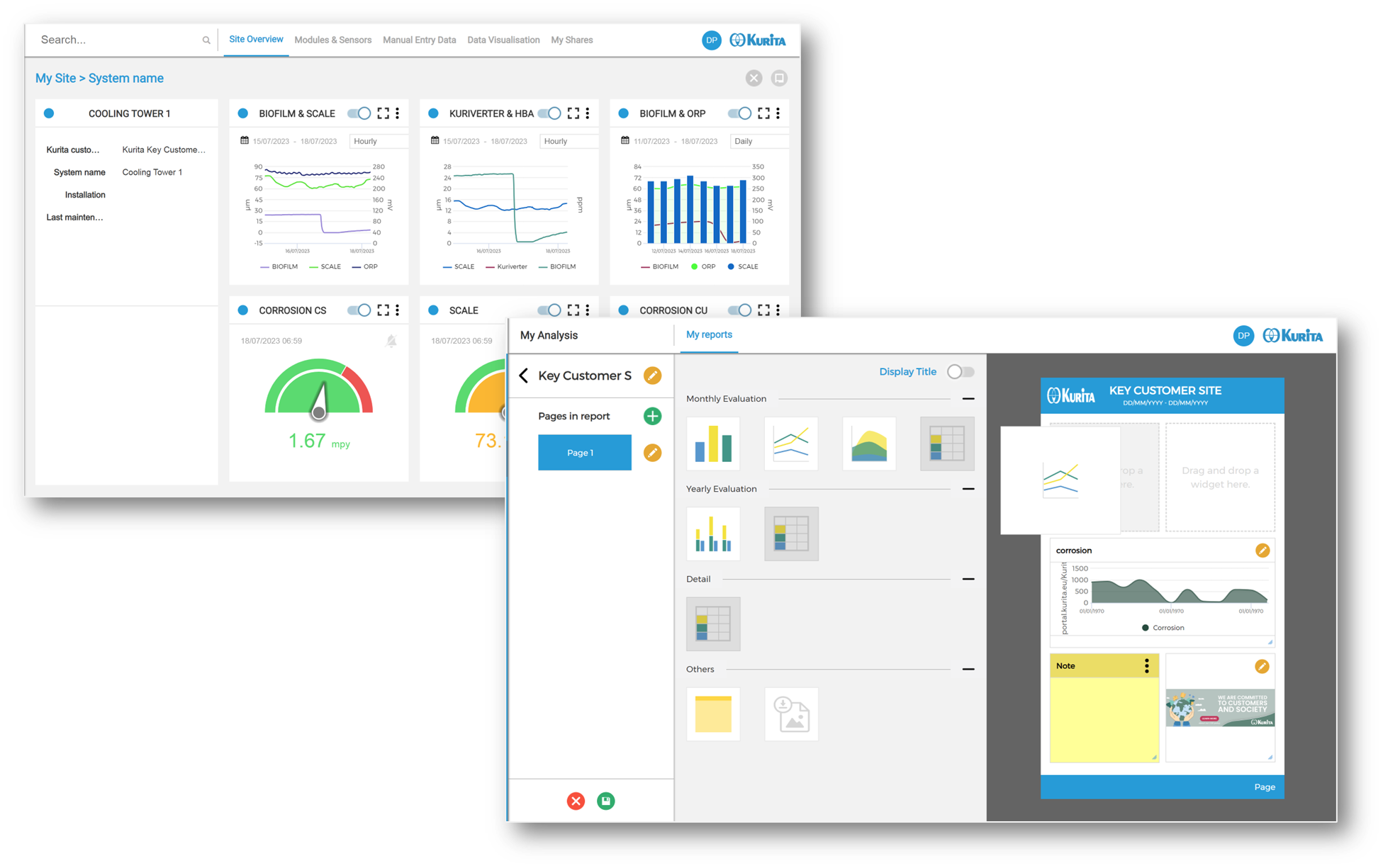

Kurita Connect360

Smart management of your treatments and systems.

With Kurita Connect360 you can collect automatic data, monitor 24/7 your system, generate accurate reports and much more.

Cetamine® FB Technology - Next Generation Boiler Water Treatment in Food & Beverage Industry

Water is a key resource in the food & beverage industry.

In this sensitive industry high steam purity is essential to assure the required product quality. Safe and efficient boiler operation is another basic requirement to assure long term protection against corrosion to avoid system failures.

Cetamine® FB Technology can be safely applied in boiler systems where the generated steam has either direct or indirect contact to food.

Customer Review

1) Ideal distribution of active components in the whole network resulting in optimal alkalization.

2) Excellent protection against corrosion.

3) Economical savings in terms of lower product consumption.

4) Full technical support for the treatment concept implementation.

5) Implementation of a non-toxic treatment program free of cyclohexylamine CPCU is entirely satisfied with Kurita’s Cetamine Technology and recommends its usage for boiler networks.

1) Important water & energy savings have been realized due to blow-down reduction

2) Steam quality has greatly improved

3) Inspections have shown TLEs and drums effectively protected against corrosion by a thin, uniform, adherent magnetite layer

4)Turbines are exceptionally clean and free of corrosion

5) KURITA provides a reliable Cetamine® Analytical Method to monitor the Cetamine® residual

1) Prevented gasket leaks,:

2) Our bluff amount decreased,:

3) Make up amount decreased 15%,:

4) Boiler limit values kept at standard values,:

5) The reduction of corrosion-related problems in steam lines,:

6) A 15% decrease in iron values in the boiler compared to the previous year. We would like to thank this product produced by Kurita company for the contributions it has made and will make to our company.

1) Reduction of the continuous blow-down water by up to 50%

2) Reduction of the contents of iron in the boiler water by up to 85%

3) Significant feed water quality improvement

4) Optimization of pH control in the complete steam-water pipeline system.

1) Heat Recovery Steam Generators and steam turbine internal surfaces are clean and free of corrosion.

2) Cetamine Technology has enabled the protection of components throughout the water steam cycle, including areas that could not be preserved by conventional preservation methods.

3) Reduced manpower is required for boiler and turbine preservation compared to our previous practice.

4) A reliable photometric method was provided by Kurita to monitor the residual concentration of Cetamine in water and steam samples.

1) Reduction in steam drum water conductivity.

2) Reduction in boiler blowdown.

3) Reduction in iron levels in boiler blowdown and closed cooling system.

4) Reduction in man power requirement.

5) Reduction in chemical inventory.

6) Reduction in overall treatment cost.

Benefits provided:

1) Only 1 product instead of 3 to treat the boilers and steam and condensate system,

2) Clean system surfaces with better heat transfer & boiler efficiency,

3) AII volatile treatment concept leading to significant lower blow-down,

4) Savings in water & energy,

5) Reduction of total iron leading to better protection of the boilers especially during shut-down periods,