At Kurita, we create shared value with customers and the environment. That’s why we developed our Value+ product portfolio, which aims to enhance productivity while reducing the total cost of operations (TCO) and supporting sustainability goals.

Our range of technologies, products, and services effectively minimizes water, waste, and energy consumption while also lowering carbon emissions.

OSCAR - The ultimate solution for membrane maintenance

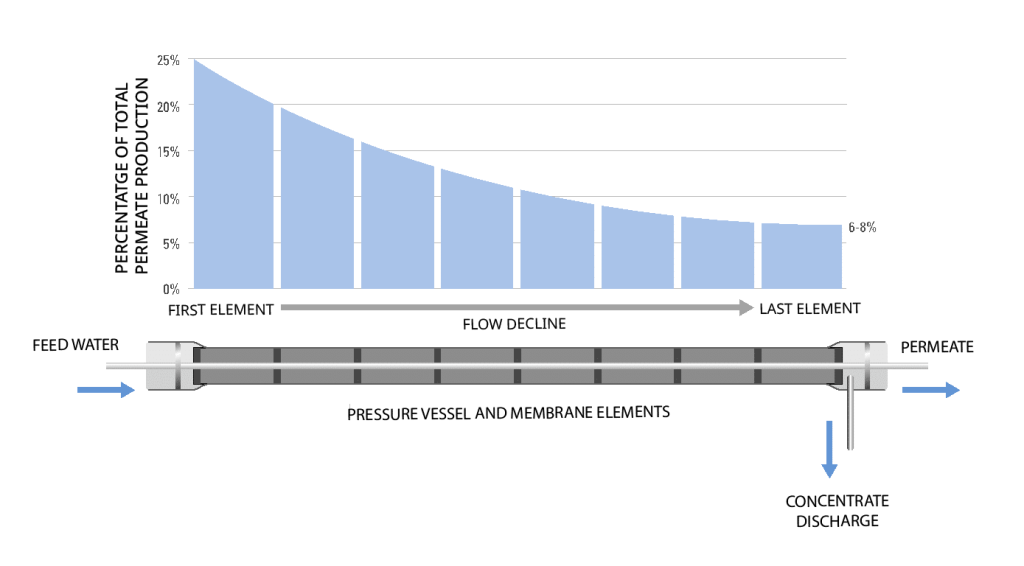

Effective maintenance is critical to optimising the performance of reverse osmosis systems and maximising the productive life of membrane elements. Every system will have its own unique requirements based on its feed water quality and hydrodynamic characteristics. In multiple element systems, each element will be exposed to different fouling conditions.

The OSCAR process represents the best way to maintain a reverse osmosis system, allowing for the design of bespoke reconditioning programs, adapted during the procedure to achieve the best possible results. Crucially, individual membrane elements receive attention not possible during in-situ cleaning.

There is no better way to service membrane elements and protect the capital investment they represent than with OSCAR servicing.

OSCAR Unique Advantages

Technical Benefits

Maximise System Performance

Maintain permeate quality and production rates by keeping each membrane element in the best possible condition.

Reduce Operational Costs

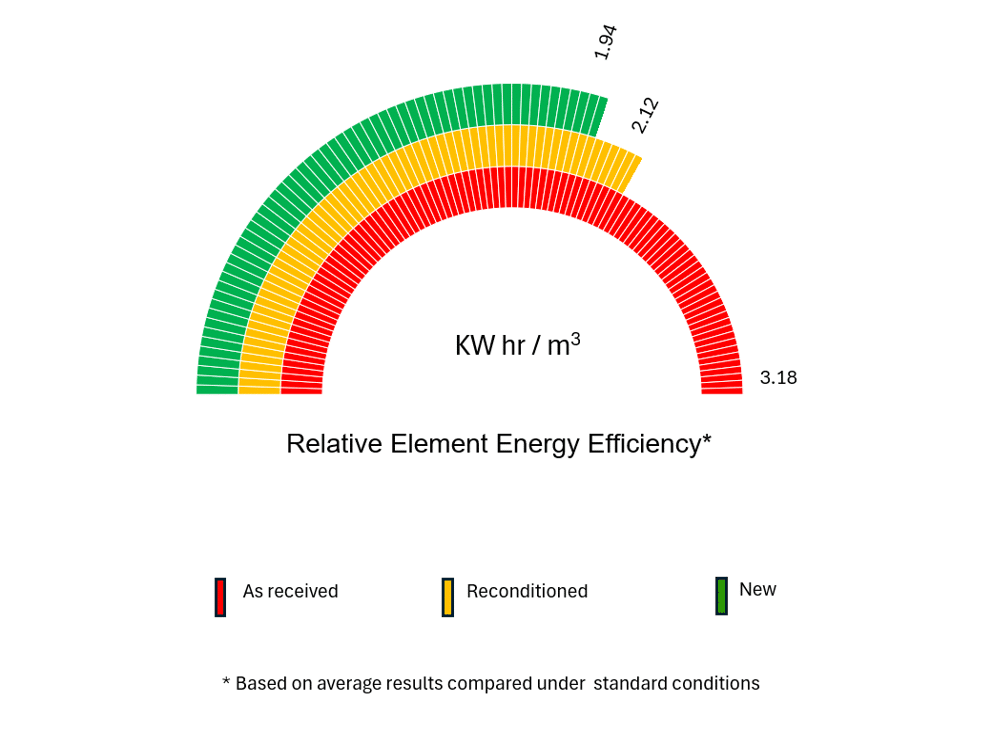

Reduce operational energy costs, minimize system shut downs, reduce water consumption and reduce membrane replacement costs.

Improve System Knowledge

Gain an understanding of your system condition, identify where fouling occurs and plan maintenance schedules and investments based on increased visibility.

Optimize membrane life

Reduce waste and enhance your organisation’s resource efficiency.

Flexibility

Instant access to the whole range of cleaning chemicals and flow dynamics, allowing for tailored maintenance regimes. OSCAR is the ideal solution for sites with inadequate Clean-in-place systems.

Operator Friendly

Eliminate the need for chemical handling, storage and stock control.

Individual Element Testing

Profile the system, understand where fouling accumulates, focus attention where it is required. Never discard membrane elements that have remaining serviceable life. Understand in advance how the system will perform after cleaning.

Save Time

Avoid repeatedly cleaning and searching for the right cleaning solution.

Environmental Benefits

Water Saving

Maximise water efficiency by ensuring effective cleaning.

Minimise Waste

Minimise unnecessary mixed plastics waste associated with membrane element disposal.

Energy Saving

Properly reconditioned elements require lower operating pressures reducing ongoing energy consumption.

Decrease CO2 emissions

Reduce the energy consumption associated with higher operating pressures and less effective cleaning operations.

Why consider regular servicing?

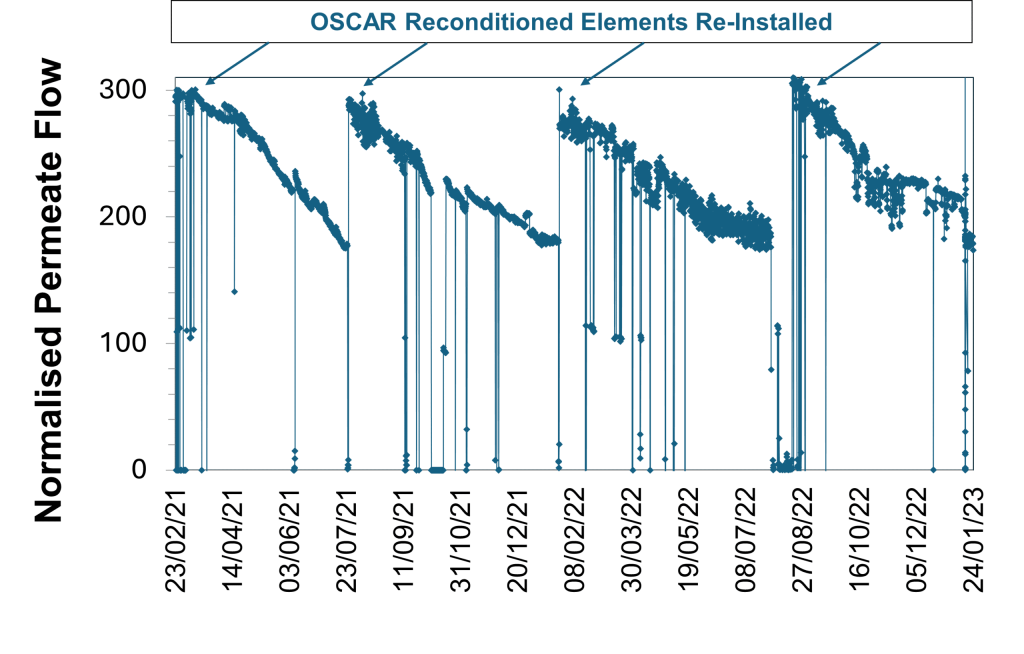

Most capital equipment will last longer with a regular service and maintenance program. Attending to any drift in performance early makes it easier to correct and prevents permanent degradation. Membrane elements are no different. Their performance will degrade gradually, and a maintenance program is essential for system efficiency and extending membrane life.

Including an OSCAR service in the maintenance program can ensure the best outcomes for any system.

What are the benefits of choosing OSCAR over typical Clean in Place (CIP) maintenance?

The OSCAR service rejuvenates fouled elements, recovering system performance and restoring energy efficiency.

OSCAR is specifically designed to provide optimum cleaning conditions for each element, often not possible when applying in situ CIP. Each element is individually performance tested, ensuring that you know what condition your system will be in at start-up, and you never dispose of recoverable membranes.

When you use the OSCAR service you can forget all the headaches associated with CIP. We provide the technicians, the high-quality water, and the chemical handling. We take-on the discharge processing.

Why it’s important to consider a reconditioning service before buying new elements.

Spiral wound membrane elements are composed of mixed plastic materials, all of which are derived from oil. Mixed plastics of this kind contribute more than double their weight in carbon dioxide to the atmosphere if incinerated and are not readily biodegradable when disposed of in landfills. Additionally, membrane elements have an embedded energy cost from the manufacturing process, and they, and their raw materials, are usually sourced from remote locations, meaning transport further adds to their carbon footprint.

Extending the serviceable life of membrane elements to their limit reduces the demand for more manufacturing and its associated environmental impact, allowing system operators to work towards their sustainability goals.

Global OSCAR in numbers

Years in Operation

Number of Customers Served

Number of Elements Reconditioned

Largest System Serviced

Typical System Size

Number of dedicated technicians

OSCAR success story

A regular OSCAR service program helps an offshore oilfield platform maintain their system’s performance despite extremely challenging operating conditions and rapid fouling.

OSCAR results:

- Predictable outcomes

- High-quality permeate

- Good permeate flows

- Reduction in the platform’s membrane replacement requirements.

OSCAR Service Process

-

Membrane elements are removed from the system and sent to our facility.

-

Each membrane element is individually inspected, performance-tested and bench-marked against the manufacturer’s specification

-

Elements are reconditioned in the OSCAR system, with up to three process cycles. Each cycle includes multiple steps, utilizing different cleaners and optimized flow conditions.

-

Between each cycle the elements are performance tested and improvements are tracked.

-

Rejuvenated elements are vacuum-packed with preservatives, boxed and returned to customers.

-

Operators receive a full report documenting the level of improvement for each element, their final condition, recommendations and guidance on re-installation. Element performance is tracked from the previous service to allow planning.

-

The membrane elements are reinstalled into the system or stored until required.

-

When the system starts up the performance is at the expected level, with no unexpected quality or operational issues.

OSCAR Savings Calculator

Easily calculate the potential savings you can achieve by cleaning your membranes using OSCAR services

Resources

Case Study - OSCAR Restores Nanofiltration System

OSCAR: Frequently Asked Questions

OSCAR Leaflet

Related Solutions

RoQuest™

RoQuest™ CoagulantMembrane-compatible coagulants to boost filter performance Coagulation and Filtration Our extensive autopsy library shows colloidal and particulate fouling are very frequent causes of fouling in reverse osmosis (RO) systems, resulting in reductions in performance efficiency and membrane element life. Multi-media filtration is one of the most common and economical

RoClean™ Cleaners

RoClean™ Membrane CleanersProvide efficient and cost-effective removal of many different foulant and scales. Innovative Solutions for a Better World Learn more At Kurita, we create shared value with customers and the environment. That’s why we developed our Value+ product portfolio, which aims to enhance productivity while reducing the total cost

Avista™ Membrane Treatment Solutions

CREATIVE CHEMISTRY.SMART SOLUTIONS. Download Brochure Avista, a global brand of Kurita for membrane treatment solutions Avista is a leading global brand recognized by operators, system designers, membrane manufacturers and equipment suppliers for application expertise and innovative membrane solutions. Kurita offers local support services to optimize membrane system performance and a