På Kurita skapar vi delat värde med våra kunder och miljön. Det är därför vi har utvecklat vår Value+-produktportfölj, som syftar till att förbättra produktiviteten samtidigt som den totala driftskostnaden (TCO) minskar och hållbarhetsmålen stöds.

Vårt utbud av teknik, produkter och tjänster minimerar effektivt vatten-, avfalls- och energiförbrukningen och minskar samtidigt koldioxidutsläppen.

Ekonomiska besparingar för ditt kokningssystem

Kuritas omfattande Cetamin® Tekniken ger ett utmärkt skydd mot korrosion i pannsystem. Cetamine består av filmbildande ämnen och skapar en hydrofobisk skyddsfilm som fungerar som en barriär mellan vatten och metall och effektivt förhindrar korrosion och avlagringar.

Som ett helt ekologiskt behandlingsprogram är Cetamine® möjliggör optimerade renblåsningshastigheter med högre koncentrationscykler, vilket leder till betydligt lägre förbrukning av färskvatten, energibesparingar och minskade utsläpp av CO2 utsläpp

Tillämpningar

- Låg- till högtryckssystem

- Högt tryck (turbiner)

- Livsmedelsindustri (direkt kontakt med livsmedel)

- Alkalisk utkokning

- Våt och torr konservering

Egenskaper och fördelar med Cetamine®-tekniken

Skydd

- Exceptionellt skydd mot korrosion och avlagringar i hela vatten-/ångsystemet

- Långsiktigt skydd vid diskontinuerlig drift och systemavstängning

Effektivitet

- Rengör systemets ytor

- Bättre värmeöverföring och pannans effektivitet

- Högre koncentrationscykler

Besparingar

- Minskad vatten- och energiförbrukning

- Ekonomisk besparing

Begränsning av flödesaccelererad korrosion (FAC)

- Enfas FAC

- Tvåfas FAC

Enkel hantering och kontroll

- 1 produkt istället för 3

- Flödesmätarstyrd dosering proportionell mot tillskottsvatten

- Onlineövervakning och dosratskontroll

Påverkan på miljön

- Minskad nedblåsning och vattenutsläpp

- Minskad CO2 utsläpp

Livsmedelssäkerhet

- Uppfyller internationella livsmedelsbestämmelser

Cetamine® kalkylator för besparingar

Förväntade besparingar med Cetamine i ditt pannsystem.

Övervakning och digital styrning

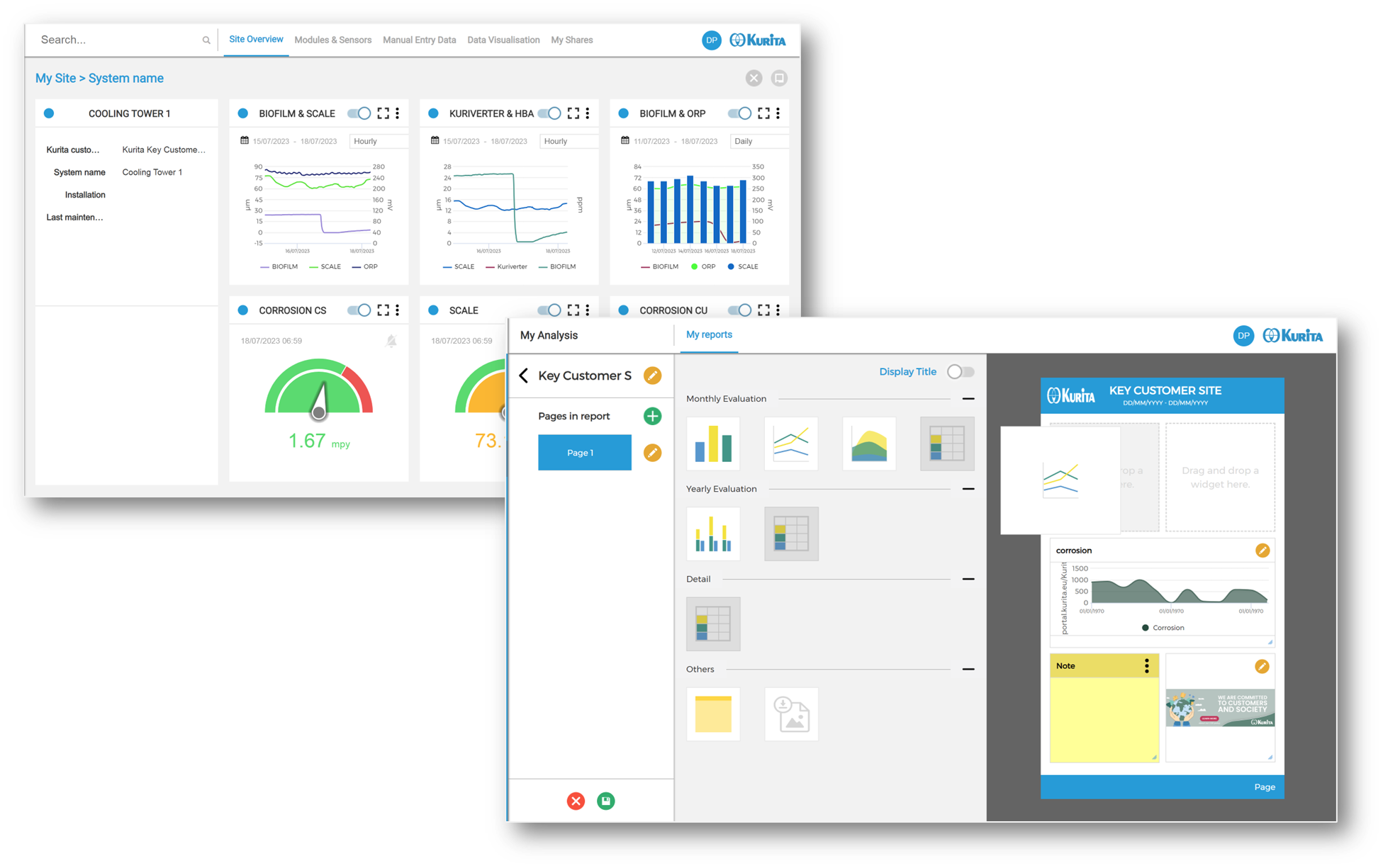

Kurita Connect360

Smart hantering av dina behandlingar och system.

Med Kurita Connect360 kan du samla in automatiska data, övervaka ditt system 24/7, generera exakta rapporter och mycket mer.

Cetamine® FB Technology - nästa generations pannvattenrening inom livsmedels- och dryckesindustrin

Vatten är en viktig resurs inom livsmedels- och dryckesindustrin.

I denna känsliga bransch är hög renhet hos ångan avgörande för att säkerställa den produktkvalitet som krävs. Säker och effektiv panndrift är ett annat grundläggande krav för att säkerställa långsiktigt skydd mot korrosion och undvika systemfel.

Cetamine® FB Technology kan användas på ett säkert sätt i pannsystem där den genererade ångan kommer i direkt eller indirekt kontakt med livsmedel.

Kundrecension

1) Idealisk fördelning av aktiva komponenter i hela nätverket vilket resulterar i optimal alkalisering.

2) Utmärkt skydd mot korrosion.

3) Ekonomiska besparingar i form av lägre produktförbrukning.

4) Fullständigt tekniskt stöd för implementering av behandlingskonceptet.

5) Implementering av ett giftfritt behandlingsprogram fritt från cyklohexylamin CPCU är helt nöjda med Kuritas Cetamine Technology och rekommenderar att den används för pannnätverk.

1) Viktiga vatten- och energibesparingar har uppnåtts tack vare minskad nedblåsning

2) Ångkvaliteten har förbättrats avsevärt

3) Inspektioner har visat att TLE och trummor är effektivt skyddade mot korrosion genom ett tunt, enhetligt och vidhäftande magnetitskikt

4) Turbinerna är exceptionellt rena och fria från korrosion

5) KURITA tillhandahåller en tillförlitlig analysmetod för Cetamine® för att övervaka resthalten av Cetamine®.

1) Förhindrar läckage i packningar:

2) Vår bluffmängd minskade,:

3) Kompensationsbeloppet minskade 15%,:

4) Gränsvärdena för pannan hålls på standardvärdena:

5) Minskning av korrosionsrelaterade problem i ångledningar:

6) En minskning av järnvärdena i pannan med 15% jämfört med föregående år. Vi vill tacka den här produkten som tillverkas av Kurita-företaget för de bidrag den har gett och kommer att ge till vårt företag.

1) Minskning av det kontinuerliga avblåsningsvattnet med upp till 50%

2) Minskning av järninnehållet i pannvattnet med upp till 85%

3) Betydande förbättring av matarvattnets kvalitet

4) Optimering av pH-regleringen i det kompletta rörledningssystemet för ånga och vatten.

1) Ånggeneratorer med värmeåtervinning och ångturbinens inre ytor är rena och fria från korrosion.

2) Cetamine Technology har gjort det möjligt att skydda komponenter i hela vattenångcykeln, inklusive områden som inte kan bevaras med konventionella konserveringsmetoder.

3) Mindre personal krävs för att bevara pannor och turbiner jämfört med tidigare.

4) Kurita tillhandahöll en tillförlitlig fotometrisk metod för att övervaka den kvarvarande koncentrationen av Cetamine i vatten- och ångprover.

1) Minskad vattenledningsförmåga i ångtrumman.

2) Minskning av pannans blåstömning.

3) Minskade järnhalter i pannans renblåsning och i det slutna kylsystemet.

4) Minskning av behovet av arbetskraft.

5) Minskning av kemikalielagret.

6) Minskning av den totala behandlingskostnaden.

Förmåner som tillhandahålls:

1) Endast 1 produkt istället för 3 för att behandla pannorna och ång- och kondensatsystemet,

2) Rena systemytor med bättre värmeöverföring och pannverkningsgrad,

3) AII-konceptet för behandling av flyktiga ämnen leder till betydligt lägre utblåsning,

4) Besparingar i vatten och energi,

5) Minskning av den totala järnhalten, vilket leder till bättre skydd av pannorna, särskilt under avstängningsperioder,