Kurita NT Technology – innovative biofouling control.

Biofouling is a major problem for the efficient operation of an open cooling water system. Slime produced by bacteria can very quickly form a strong stable biofilm on heat exchanger, pipework and tower fill surfaces with undesired consequences:

- Fast development – can be within days

- Decrease heat transfer – 1µm of biofilm = 5 – 10 % less heat transfer

- Decreased Flows – increased pumping cost and lost production

- Blocked Tower Fill – reduced cooling efficiency

- Increased risk of high Legionella counts

- Increased risk of under deposit corrosion

Traditionally to control biofouling and biofilms, combinations of biocides and bio-dispersants are used at high cost and risk of increased corrosion

Kurita now offers an innovative alternative – Kurita NT Technology.

What is Kurita NT Technology?

Kurita NT Technology is a stabilised inorganic chlorine compound with many unique benefits.

- Low dosage efficiency

- Penetrates biofilm due to its low oxidation characteristic

- Is not corrosive to metal surfaces like traditional free chlorine and bromine

- Is non-foaming

Product Video

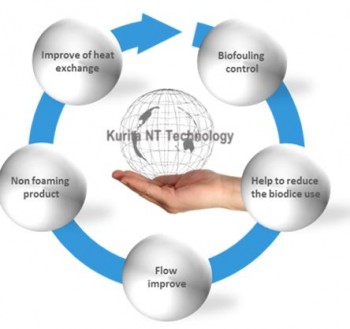

Benefits of Kurita NT technology

Kurita NT Technology is a stabilised inorganic chlorine compound with many unique benefits.

- Low dosage efficiency

- Penetrates biofilm due to its low oxidation characteristic

- Is not corrosive to metal surfaces like traditional free chlorine and bromine

- Is non-foaming

Kurita NT Technology Product Range:

The Kurita® NT system is a highly effective and patented system developed by Kurita for biofilm control in cooling water systems.

Preventing biofouling in your cooling system will :

- Maximise

- Heat Transfer and Production

- Minimise

- Pumping Energy, Corrosion, Legionella Risk and Chemical Costs

Kurita NT Technology & HydroBio® Advance?

- Continuously monitor the development of biofilm

- Optimise NT Technology dosage

- Give real time feedback on dosing adjustments