Tecnologia di condensazione

Tecnologia di condensazione Kurita Dropwise migliora la produttività e aumenta l'efficienza del trasferimento di calore negli impianti industriali e negli scambiatori di calore. I prodotti ad alta tecnologia progettati per le diverse esigenze industriali vengono dosati in modo continuo nella linea del vapore davanti al dispositivo di destinazione, creando una pellicola idrorepellente sulle superfici di condensazione.

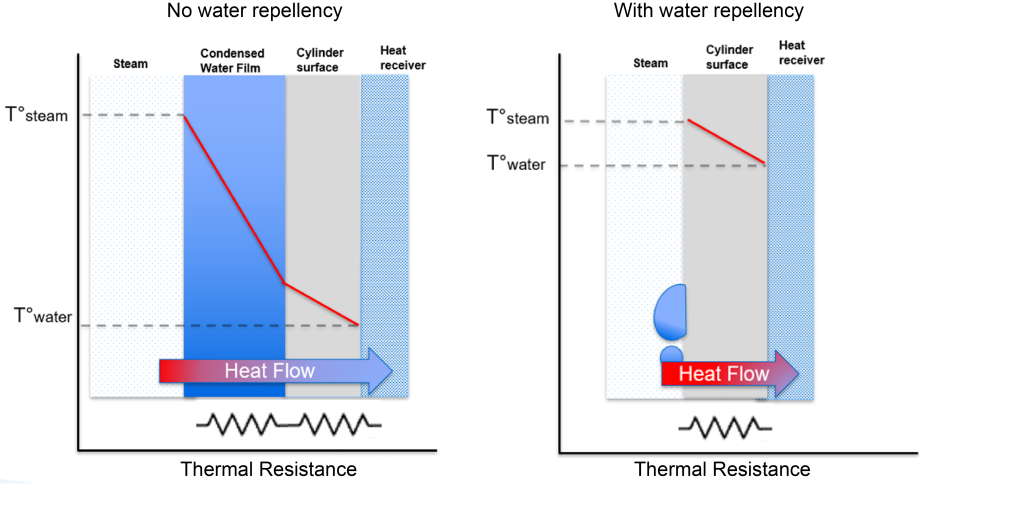

L'idrorepellenza modifica il meccanismo di condensazione da naturale (condensazione filmica) a Condensazione a gocciaimpedendo all'acqua di formare uno strato isolante. Il risultato è un significativo miglioramento dell'efficienza di trasferimento del calore, con conseguente riduzione del consumo di vapore e delle emissioni di CO2 e una maggiore produttività.

Tecnologia Kurita Dropwise è una tecnologia sostenibile che consente di ridurre le emissioni di anidride carbonica, sostenendo lo sviluppo di una società eco-compatibile.

Caratteristiche e vantaggi della tecnologia

+30% Maggiore efficienza di trasferimento del calore

La nostra soluzione avanzata elimina la barriera dello strato di condensa, aumentando notevolmente il flusso di calore e le prestazioni del sistema.

Significativi risparmi energetici e di costi

+16% di produzione di energia e capacità di compressione nelle turbine e nei compressori a vapore, oltre a + 8% di risparmio di vapore nei ribollitori delle colonne di distillazione.

Riduzione del livello di vuoto

Riduzione dei livelli di vuoto nei condensatori di vapore per una maggiore stabilità operativa

Riduzione delle emissioni di carbonio

La riduzione del consumo di vapore e di combustibile si traduce direttamente in minori emissioni di CO₂, aiutandovi a raggiungere gli obiettivi ambientali.

Non sono necessarie grandi spese in conto capitale

La tecnologia di condensazione Kurita Dropwise si integra facilmente nelle linee di vapore esistenti con un investimento minimo.

Innovazione premiata

Ha ricevuto il Gran Premio per la Conservazione dell'Energia per il miglioramento dell'efficienza del trasferimento di calore.

Applicazioni

La tecnologia Kurita Dropwise ha dimostrato di funzionare in diversi settori.

- Condensatori nella generazione di energia, nella petrolchimica e nelle raffinerie

- Processi di essiccazione nell'industria della cellulosa, della carta e del tessile

- Processo di vulcanizzazione nella produzione di pneumatici

- Reattori nell'industria chimica

- Ondulatori nella produzione di cartone

- Macchine per la stampa del cartone stampato

- Linea continua di zincatura a caldo (CGL) nell'industria siderurgica

- Macchine da stampa per la produzione di compensato

- Evaporatori nella produzione alimentare e nell'industria della cellulosa

- Produzione di guanti in gomma

- Riscaldatori ad aria nella produzione di resina

- Compressori nei processi di produzione di idrocarburi

Galleria video

1. Video introduttivo

2. Industria petrolchimica

3. Industria della carta

Calcolatore di risparmio Kurita Dropwise

Risparmio previsto nel vostro sistema

Premio Sasaki

Kurita riceve il premio Sasaki dalla Japan Technical Association of the Pulp and Paper Industry per FINE STEAM™ basato sulla tecnologia Kurita Dropwise Condensation (2023).

Gran premio per la conservazione dell'energia

Kurita ha vinto il Grand Prize 2019 per la conservazione dell'energia per il miglioramento del trasferimento di calore attraverso la tecnologia di condensazione a goccia, il secondo riconoscimento dopo aver ricevuto il Chairman's Award 2017 per Tecnologia DReeM Polymer.

Storia di successo del cliente

1) Produttività +3%

2) -6% Consumo di gas

3) 108 T/anno di CO2 Risparmio di emissioni

Possiamo raccomandare Kurita Europe come partner affidabile per tutte le domande relative al trattamento dell'acqua e alla tecnologia Kurita Dropwise per aumentare l'efficienza del processo di produzione della carta.

Inoltre, la condensa del vapore contenente questa sostanza chimica può essere reimmessa nel sistema come acqua di alimentazione della caldaia.

- La turbina di condensazione ha mantenuto i livelli di vuoto del condensatore nonostante l'aumento delle temperature dell'acqua di mare dal 2021 al 2023, soprattutto in estate. Questo miglioramento ha comportato un aumento di oltre 10% della potenza del compressore del gas.

- Il condensato di vapore con l'additivo Dropwise (15-20 mg/L) può essere riutilizzato come acqua di alimentazione della caldaia.

- L'assistenza tecnica rimane tempestiva e pertinente.

Inoltre, l'assistenza tecnica fornita è stata tempestiva e pertinente.

Il consumo di vapore per tonnellata di carta è stato ridotto in media di 7% per tutte le grammature, con alcune che hanno raggiunto le 10%. Ciò ha comportato una significativa riduzione dei costi del combustibile e delle emissioni di CO2 emissioni.

Casi di studio

Miglioramento operativo mediante aumento del trasferimento di calore nel condensatore di una caldaia per la produzione di energia elettrica

Aumento dell'efficienza di trasferimento del calore del condensatore e aumento della caduta di calore della turbina a vapore.

Miglioramento del funzionamento nella produzione di cartone ondulato

Soluzioni correlate

Tecnologia Kurita Dropwise - Industria della carta

Tecnologia Kurita Dropwise - Miglioramento dell'efficienza dell'essiccatoio della carta Ottimizzazione dell'efficienza del trasferimento di calore nei sistemi di essiccazione della carta Innovativa tecnologia Kurita Dropwise per gli essiccatoi della carta L'essiccazione

Kurita Connect 360

La piattaforma digitale di Kurita per la gestione globale dell'acqua migliora le prestazioni del sistema fornendo raccomandazioni intelligenti e monitoraggio continuo delle applicazioni di trattamento dell'acqua.