Bei Kurita schaffen wir gemeinsame Werte mit Kunden und der Umwelt. Deshalb haben wir unser Value+ Produktportfolio entwickelt, das darauf abzielt, die Produktivität zu steigern und gleichzeitig die Gesamtbetriebskosten (TCO) zu senken und Nachhaltigkeitsziele zu unterstützen.

Unser Angebot an Technologien, Produkten und Dienstleistungen minimiert effektiv den Wasser-, Abfall- und Energieverbrauch und senkt gleichzeitig die Kohlenstoffemissionen.

Technologie der Kondensation

Kurita Tropfenweise Kondensationstechnologie verbessert die Produktivität und steigert die Effizienz der Wärmeübertragung in Industrieanlagen und Wärmetauschern. Hochtechnologische Produkte, die für unterschiedliche industrielle Anforderungen entwickelt wurden, werden kontinuierlich in die Dampfleitung vor dem Zielgerät dosiert und bilden einen wasserabweisenden Film auf den Kondensationsflächen.

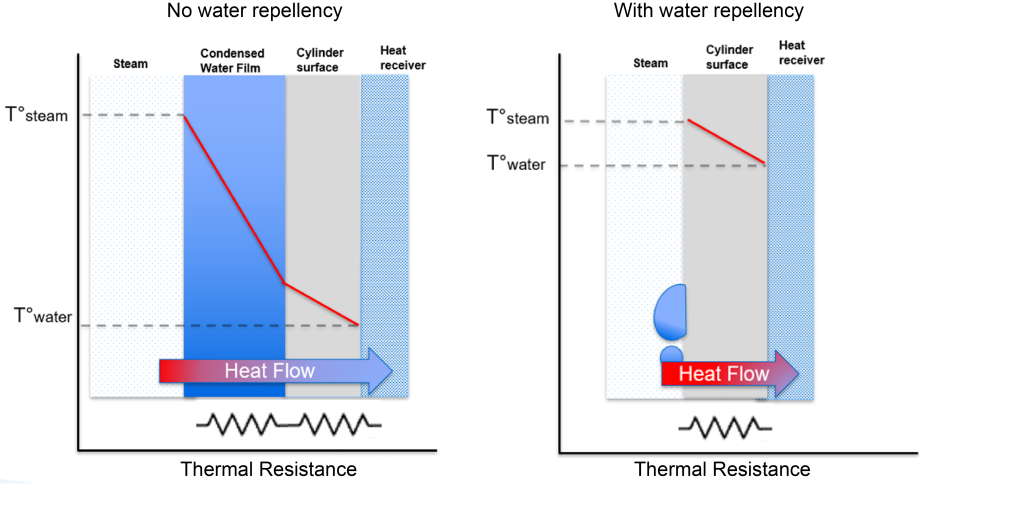

Die Wasserabstoßung verändert den Kondensationsmechanismus von natürlicher (filmweiser Kondensation) zu Tropfenweise KondensationDadurch wird verhindert, dass Wasser eine isolierende Schicht bildet. Das Ergebnis ist eine erhebliche Verbesserung der Wärmeübertragungseffizienz, was zu einem geringeren Dampfverbrauch, weniger CO2 Ausstoß und erhöhte Produktivität.

Kurita Dropwise-Technologie ist eine nachhaltige Technologie, die zu einer Verringerung der Kohlendioxidemissionen führt und die Entwicklung einer umweltfreundlichen Gesellschaft unterstützt.

Merkmale und Vorteile der Technologie

Höherer Wirkungsgrad der Wärmeübertragung

Nicht anfängliche CapEX-Kosten

Gesteigerte Produktivität

Geringerer Dampfverbrauch

Anwendungen

Die Kurita Dropwise-Technologie hat sich in einer Vielzahl von Branchen bewährt.

- Kondensatoren in Stromerzeugung, Petrochemie und Raffinerien

- Trocknungsprozesse in der Zellstoff-, Papier- und Textilindustrie

- Vulkanisierungsprozess bei der Reifenherstellung

- Reaktoren in der chemischen Industrie

- Wellpappenanlagen in der Kartonherstellung

- Maschinen für die Herstellung von bedrucktem Karton

- Kontinuierliche Feuerverzinkungsanlage (CGL) in der Stahlindustrie

- Pressmaschinen in der Sperrholzproduktion

- Verdampfer in der Lebensmittelproduktion und Zellstoffindustrie

- Herstellung von Gummihandschuhen

- Lufterhitzer in der Harzproduktion

- Kompressoren in der Kohlenwasserstoffproduktion

Video-Galerie

1. Einführungsvideo

2. Petrochemische Industrie

3. Papierindustrie

Kurita Dropwise Einsparungsrechner

Voraussichtliche Einsparungen in Ihrem System

Sasaki-Preis

Kurita erhält den Sasaki Award von der Japan Technical Association of the Pulp and Paper Industry für FINE STEAM™ basierend auf der Kurita Dropwise Condensation Technology (2023).

Großer Preis für Energieeinsparung

Kurita erhielt den Großen Preis für Energieeinsparung 2019 für die verbesserte Wärmeübertragung durch die tropfenweise Kondensationstechnologie, die zweite Auszeichnung nach dem Chairman's Award 2017 für DReeM Polymer™ Technologie.

Erfolgsgeschichte eines Kunden

1) +3% Produktivität

2) -6% Gasverbrauch

3) 108 T/Jahr CO2 Einsparung von Emissionen

Wir können Kurita Europe als zuverlässigen Partner in allen Fragen der Wasseraufbereitung sowie der Kurita Dropwise Technology zur Steigerung der Effizienz des Papierherstellungsprozesses empfehlen.

Außerdem kann das Dampfkondensat, das diese Chemikalie enthält, als Kesselspeisewasser in das System zurückgeführt werden.

1) Die Technologie hat zu einem stabilen Betrieb der Prozesseinheit der Raffinerie beigetragen.

2) Die Kurita Dropwise Condensation Technology für Gaskompressoren, die von einer Kondensationsturbine angetrieben werden, hat das Vakuumniveau im Kondensator trotz steigender Meerwassertemperaturen von 2021 bis 2023 aufrechterhalten, insbesondere im Sommer. Diese Verbesserung führte zu einer Steigerung der Gasverdichterleistung um über 10%.

2) Dampfkondensat mit Dropwise-Zusatz (15-20 mg/L) kann als Kesselspeisewasser wiederverwendet werden.

3) Die technische Hilfe bleibt zeitnah und relevant.

Darüber hinaus wurde die technische Unterstützung zeitnah und sachgerecht geleistet.

Fallstudien

Verwandte Lösungen

S.sensing™ VP

Das S.sensing™ VP-Konzept von Kurita überwacht Wasseraufbereitungssysteme auf intelligente Weise, bietet Einblicke, identifiziert verbesserungswürdige Bereiche und hilft bei der Reduzierung des Energieverbrauchs, um Nachhaltigkeitsziele zu erreichen.

Kurita Connect 360

Die digitale Kundenplattform von Kurita für das globale Wassermanagement verbessert Ihre Systemleistung durch kontinuierliche intelligente Empfehlungen und Überwachung Ihrer Wasseraufbereitungsanwendungen.