DReeM Polymer®

Dispersion Removal effects Management

At Kurita, we create shared value with customers and the environment. That’s why we developed our Value+ product portfolio, which aims to enhance productivity while reducing the total cost of operations (TCO) and supporting sustainability goals.

Our range of technologies, products, and services effectively minimizes water, waste, and energy consumption while also lowering carbon emissions.

DReeM Polymer® - Revolutionary Dispersion Removal Effect Management Polymer for Steam Generators and Boiler Systems

DReeM Polymer® is Kurita’s award-winning solution for maintaining optimal performance in steam generators and boiler systems. This advanced polymer not only prevents scale formation but also removes existing hardness and silica deposits, ensuring efficient and eco-friendly operations.

The unique properties of DReeM Polymer® keep heated surfaces in boiler systems free of scale, directly improving heat transfer efficiency. Clean heat transfer surfaces lead to significant energy savings and a notable reduction in CO2 emissions. Even thin layers of scale can drastically reduce boiler efficiency, requiring more fuel to generate the same amount of steam. DReeM Polymer® excels in tolerating higher levels of silica and hardness in boiler water compared to conventional treatment programs.

Wide Application Across Industries

DReeM Polymer® is extensively used in low-pressure boilers across various industries, allowing water with scale components to be utilized as boiler feed water. This facilitates the reuse of industrial water, reducing the consumption of fresh water. Notably, DReeM Polymer® is compliant with FDA § 173.310, making it suitable for use in the food industry as a boiler water additive for steam that contacts food.

DReeM Polymer Key Benefits

- Controls and removes silica and hardness scale in low-pressure boilers during normal operation

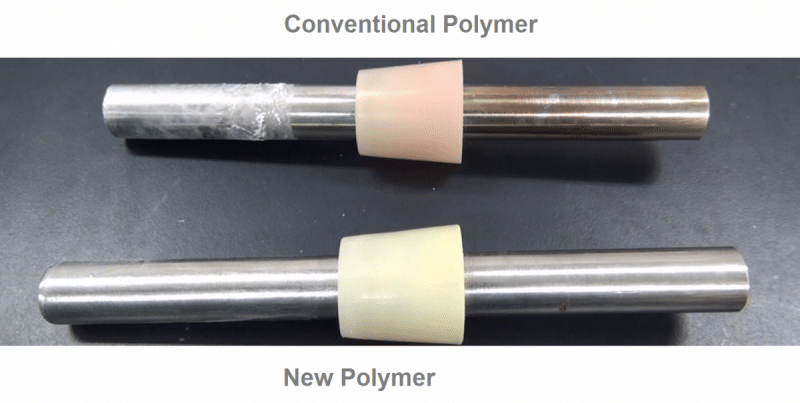

- Removes existing silica and hardness scale from boiler surfaces up to 4 times more efficient than conventional polymers

- Is a ready to use liquid descaler which is intended to be dosed additionally to the current treatment concept

- Reduces the total amount of fresh water consumption

- Fuel cost reduction by improved boiler efficiency

- Reduces operational costs by increasing boiler efficiency and lifetime

- User-friendly and easy to handle

- FDA compliant for all kinds of industries including food

DReeM Polymer® can be used as an additional descaler alongside existing treatments or with Kurita’s Cetamine® Technology.

Technology Awards

Kurita’s DReeM Polymer® has been awarded at the 49th JCIA Technology Award hosted by the Japan Chemical Industry Association (JCIA) with the Environmental Technology Award as an outstanding technology with remarkable reductions in environmental impact.

DReeM Polymer® has additionally won the Energy Conservation Center Chairman’s Award as part of 2017 Energy Conservation Grand Prize, which is organized by the Energy Conservation Center, Japan.