At Kurita, we create shared value with customers and the environment. That’s why we developed our Value+ product portfolio, which aims to enhance productivity while reducing the total cost of operations (TCO) and supporting sustainability goals.

Our range of technologies, products, and services effectively minimizes water, waste, and energy consumption while also lowering carbon emissions.

Condensation Technology

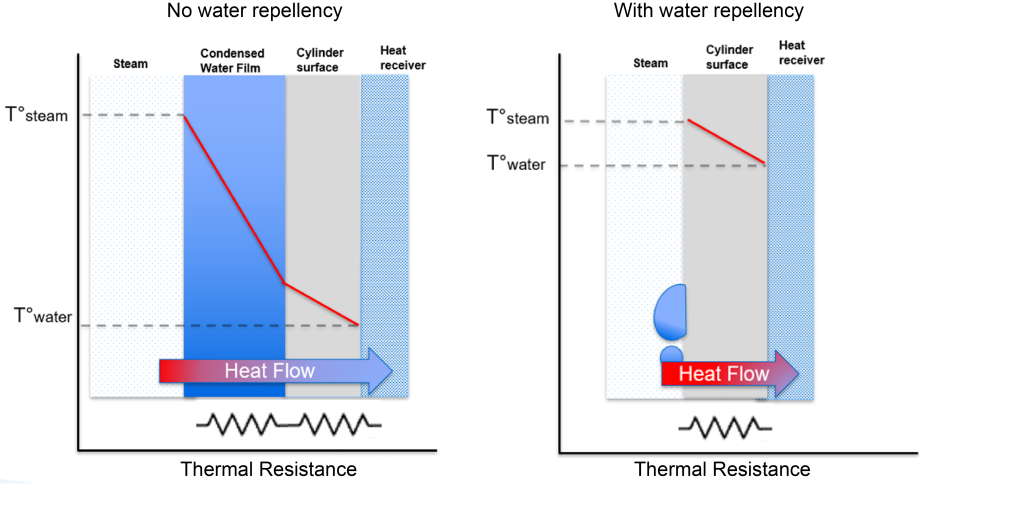

Kurita Dropwise Condensation Technology improves productivity and boosts heat transfer efficiency in industrial systems and heat exchangers. High technology products designed for different industry needs are dosed continuously into the steam line in front of the target device, creating a water repellent film on the condensation surfaces.

Water repellence changes the condensation mechanism from natural (filmwise condensation) to Dropwise condensation, preventing water from forming an isolating layer. The result is a significant improvement in heat transfer efficiency, leading to reduced steam consumption, less CO2 emission and increased productivity.

Kurita Dropwise Technology is a sustainable technology leading to a reduction of carbon dioxide emissions, supporting the development of an eco-friendly society.

Technology Features and Benefits

Higher Heat Transfer Efficiency

Non initial CapEX cost

Increased Productivity

Lower Steam Consumption

Applications

Kurita Dropwise Technology has been proven to work across a variety of industries.

- Condensers in Power Generation, Petrochemistry & Refineries

- Dryer processes in pulp, paper and textile industry

- Vulcanization process in tire production

- Reactors in Chemical Industry

- Corrugators in cardboard production

- Printed board press machines

- Continuous hot dip galvanizing line (CGL) in steel industry

- Press machines in plywood production

- Evaporators in food production and pulp industry

- Rubber gloves production

- Air heaters in resin production

- Compressors in hydrocarbon production processes

Video Gallery

1. Introductory Video

2. Petrochemical Industry

3. Paper Industry

Kurita Dropwise Savings Calculator

Predicted Savings in your system

Sasaki Award

Kurita Receives the Sasaki Award from the Japan Technical Association of the Pulp and Paper Industry for FINE STEAM™ based on Kurita Dropwise Condensation Technology (2023).

Energy Conservation Grand Prize

Kurita won the 2019 Energy Conservation Grand Prize for improved heat transfer through Dropwise Condensation Technology, the second recognition after receiving the 2017 Chairman’s Award for DReeM Polymer™ Technology.

Customer Success Story

1) +3% productivity

2) -6% Gas Consumption

3) 108 T/Year CO2 Emissions Savings

We can recommend Kurita Europe as a reliable partner for all questions regarding water treatment as well as Kurita Dropwise Technology to increase the efficiency of the paper production process.

Additionally, the steam condensate containing this chemical can be returned to the system as boiler feed water.

1) The technology has contributed to the stable operation at refinery's process unit.

2) Kurita Dropwise Condensation Technology for gas compressors driven by a condensing turbine has maintained condenser vacuum levels despite rising seawater temperatures from 2021 to 2023, particularly in summer. This improvement resulted in over a 10% increase in gas compressor output.

2) Steam condensate with Dropwise additive (15-20 mg/L) can be reused as boiler feed water.

3) Technical assistance remains timely and relevant.

Additionally, the technical assistance provided has been timely and relevant.

Case Studies

Improvement Of Heat Transfer Coefficient In Ammonia Recovery Reboiler Unit

Operation improvement in a Refinery process

Increasing Heat Transfer At Power Generation Boiler Condenser

Energy Savings And Improved Operations In The Steam System Of Rubber Glove Production Process

Related Solutions

S.sensing™ VP

Kurita’s S.sensing™ VP concept smartly monitors water treatment systems, offers insights, identifies areas for improvement, and helps reduce energy use to achieve sustainability goals.

Kurita Connect 360

Kurita’s digital customer platform for global water management enhances your system performance by providing continuous intelligent recommendations and monitoring of your water treatment applications.