In Kurita creiamo valore condiviso con i clienti e l'ambiente. Ecco perché abbiamo sviluppato il nostro portafoglio di prodotti Value+, che mira a migliorare la produttività riducendo il costo totale delle operazioni (TCO) e sostenendo gli obiettivi di sostenibilità.

La nostra gamma di tecnologie, prodotti e servizi minimizza efficacemente il consumo di acqua, rifiuti ed energia, riducendo al contempo le emissioni di carbonio.

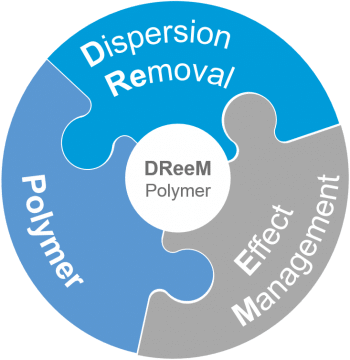

DReeM Polymer® - Polimero rivoluzionario per la gestione degli effetti di rimozione delle dispersioni per generatori di vapore e sistemi di caldaie

DReeM Polymer® è la soluzione pluripremiata di Kurita per mantenere prestazioni ottimali nei generatori di vapore e nei sistemi di caldaie. Questo polimero avanzato non solo previene la formazione di incrostazioni, ma rimuove anche i depositi di durezza e silice esistenti, garantendo un funzionamento efficiente ed ecologico.

Le proprietà uniche di DReeM Polymer® mantengono le superfici riscaldate dei sistemi di caldaie prive di incrostazioni, migliorando direttamente l'efficienza del trasferimento di calore. Superfici di trasferimento del calore pulite portano a un significativo risparmio energetico e a una notevole riduzione delle emissioni di CO2 emissioni. Anche sottili strati di calcare possono ridurre drasticamente l'efficienza della caldaia, richiedendo più combustibile per generare la stessa quantità di vapore. DReeM Polymer® eccelle nel tollerare livelli più elevati di silice e durezza nell'acqua di caldaia rispetto ai programmi di trattamento convenzionali.

Ampia applicazione in tutti i settori

DReeM Polymer® è ampiamente utilizzato nelle caldaie a bassa pressione di vari settori industriali, consentendo di utilizzare l'acqua con componenti di calcare come acqua di alimentazione della caldaia. Ciò facilita il riutilizzo dell'acqua industriale, riducendo il consumo di acqua dolce. In particolare, DReeM Polymer® è conforme ai seguenti requisiti FDA § 173.310, che lo rende idoneo all'utilizzo nella industria alimentare come additivo per l'acqua di caldaia per il vapore che entra in contatto con gli alimenti.

Vantaggi principali del polimero DReeM

- Controlla e rimuove le incrostazioni di silice e durezza nelle caldaie a bassa pressione durante il normale funzionamento.

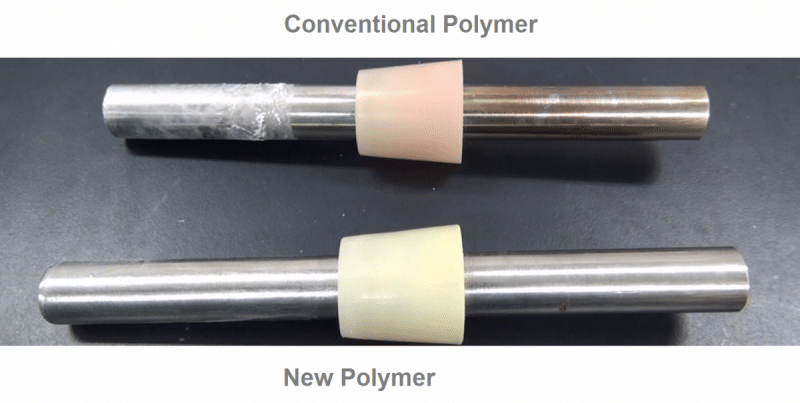

- Rimuove le incrostazioni di silice e durezza esistenti dalle superfici delle caldaie con un'efficacia fino a 4 volte superiore rispetto ai polimeri convenzionali.

- È un disincrostante liquido pronto per l'uso, da dosare in aggiunta all'attuale concetto di trattamento.

- Riduce il consumo totale di acqua dolce

- Riduzione del costo del combustibile grazie al miglioramento dell'efficienza della caldaia

- Riduce i costi operativi aumentando l'efficienza e la durata di vita della caldaia

- Facile da usare e da gestire

- Conformi alla FDA per tutti i tipi di industria, compresa quella alimentare.

DReeM Polymer® può essere utilizzato come decalcificante aggiuntivo in aggiunta a trattamenti già esistenti o con Tecnologia Cetamine® di Kurita.

Premi per la tecnologia

Kurita Polimero DReeM è stata premiata in occasione del 49° JCIA Technology Award organizzato dalla Japan Chemical Industry Association (JCIA) con il premio Premio per la tecnologia ambientale come una tecnologia eccezionale con notevoli riduzioni dell'impatto ambientale.

Polimero DReeM ha inoltre vinto l'Energy Conservation Center Chairman's Award nell'ambito del 2017 Energy Conservation Grand Prize, organizzato dall'Energy Conservation Center, in Giappone.