The Importance of Vulcanization Efficiency in Tire Manufacturing

A significant aspect of tire vulcanization is the energy required, with steam usage accounting for approximately 70% of the total energy consumption in a typical tire manufacturing plant. As a result, the efficiency of tire vulcanizers has a direct and substantial impact on both the economic performance of the facility and the quality of the finished products. Maintaining optimal heat transfer conditions in each press is therefore crucial for reducing costs and ensuring consistent, high-quality output.

Kurita Dropwise Condensation Technology: Advancing Heat Transfer Efficiency

With over 75 years in water treatment, Kurita developed the patented Dropwise Condensation Technology, now used by 500+ customers globally.

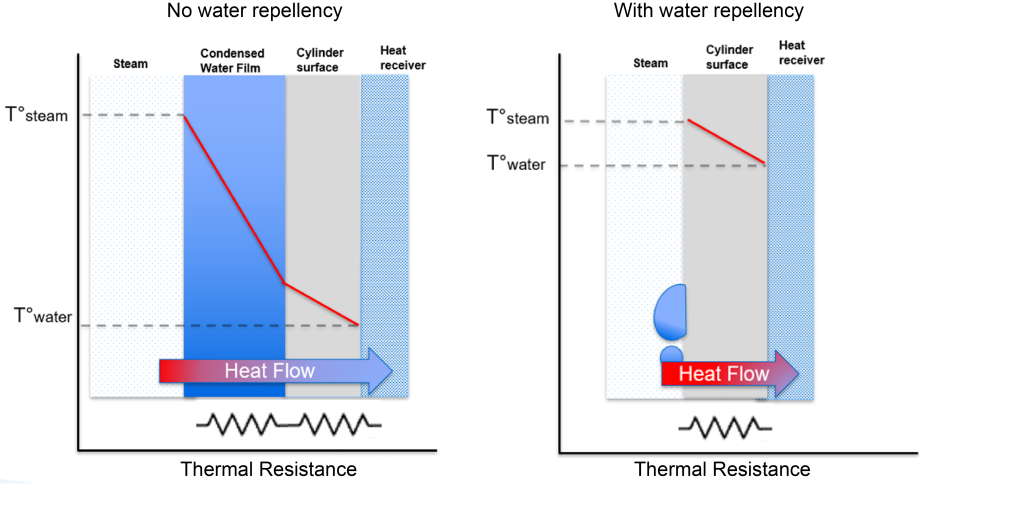

This innovative technology creates a hydrophobic monomolecular layer on condensation surfaces, protecting systems from corrosion and scaling while preventing condensate film buildup. By encouraging rapid shedding of water droplets and promoting dropwise condensation, the technology maximizes heat transfer efficiency and enhances productivity in steam systems, supporting efficient tire vulcanization processes.

Kurita DW-1108 is an advanced chemical solution engineered to optimise the curing process within the tire industry. By removing the condensate layer barrier and enhancing heat transfer, it can increase heat flow by up to 30%. This improvement results in:

- A reduction in platen steam consumption of 3–15%.

- Productivity gains of up to 10% owing to decreased curing times.

Kurita Dropwise Condensation Technology has been utilized in tire manufacturing facilities for several years, demonstrating no adverse effects on production processes, bladder lifespan, or the properties of the final product.

Application of Kurita Dropwise Condensation Technology

Energy-efficient solution with minimal capital investment, as it is service-based. The product is dosed directly into the steam line, where it quickly forms a hydrophobic film on condensation surfaces to boost heat transfer. Our local experts handle installation and dosage adjustments to ensure the best results for your plant. The technology works with standard boiler water treatments and does not affect condensate water quality.

We deliver ongoing service support through regular site visits by a dedicated Kurita sales manager. This ensures treatment is optimised, performance and water quality are continually monitored, and your team’s questions are promptly addressed.

Our performance evaluation follows a structured four-step process:

- Immerse: We evaluate your plant’s current efficiency and monitoring systems, setting clear KPIs for the demonstration phase.

- Architect: Our experts design the optimal treatment and dosing set-up tailored to your plant’s needs.

- Deliver: Over at least six months, we apply the technology and monitor results, adjusting service for maximum benefit.

- Evolve: At the end of the trial, we review the results together and, if KPIs are met, establish a long-term service partnership.

Kurita Dropwise Condensation Technology Savings Calculator

Predicted Savings in the Tire Manufacturing Process

Related Solutions

S.sensing™ VP

Kurita’s S.sensing™ VP concept smartly monitors water treatment systems, offers insights, identifies areas for improvement, and helps reduce energy use to achieve sustainability goals.

Kurita Connect 360

Kurita’s digital customer platform for global water management enhances your system performance by providing continuous intelligent recommendations and monitoring of your water treatment applications.