Innovative Kurita Dropwise Technology for Paper Dryers

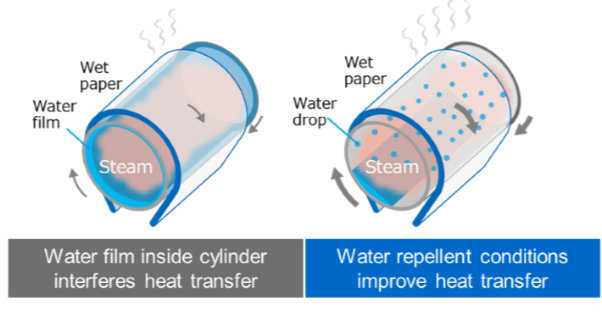

The drying process in the paper industry removes water to define the final properties of the product and is one of the most energy-intensive stages of production. Efficiency in the drying section significantly impacts overall economic performance and product quality, with heat transfer conditions in the cylinders being a key factor. These are determined by condensate removal and surface conditions such as corrosion and scaling.

Kurita introduces its patented Dropwise Condensation Technology, part of the CSV Technologies Portfolio. This innovation currently aids over 500 customers worldwide in enhancing productivity and improving heat transfer efficiency in steam condensation systems.

Kurita Dropwise forms a hydrophobic layer that protects steam systems from corrosion and scaling while preventing the formation of a condensate film on condenser tubes. This dropwise condensation effect ensures water droplets flow away from surfaces immediately upon condensation.

Technology Features and Benefits

Kurita DW-1508, a high-tech chemical product, has been specifically tailored to elevate the dryer section in the paper industry. By removing the condensate layer that acts as a barrier to heat transfer, it increases heat flow by up to 30%, delivering measurable benefits such as:

- In multi-cylinder machines, steam savings of 3-10% and a production increase of 5%.

- In corrugating machines and cartoners, a reduction in startup time by up to 50% and steam consumption savings of approximately 8%.

Note: These figures represent average values observed among Kurita customers worldwide. A specific plant evaluation is necessary to determine the precise potential benefits of Kurita Dropwise Condensation Technology.

Application of Kurita Dropwise Condensation Technology

Energy-efficient solution with minimal capital investment, as it is service-based. The product is dosed directly into the steam line, where it quickly forms a hydrophobic film on condensation surfaces to boost heat transfer. Our local experts handle installation and dosage adjustments to ensure the best results for your plant. The technology works with standard boiler water treatments and does not affect condensate water quality.

We deliver ongoing service support through regular site visits by a dedicated Kurita sales manager. This ensures treatment is optimised, performance and water quality are continually monitored, and your team’s questions are promptly addressed.

Our performance evaluation follows a structured four-step process:

- Immerse: We evaluate your plant’s current efficiency and monitoring systems, setting clear KPIs for the demonstration phase.

- Architect: Our experts design the optimal treatment and dosing set-up tailored to your plant’s needs.

- Deliver: Over at least six months, we apply the technology and monitor results, adjusting service for maximum benefit.

- Evolve: At the end of the trial, we review the results together and, if KPIs are met, establish a long-term service partnership.

Kurita Dropwise Savings Calculator

Predicted Savings in Dryer Cylinders in the Paper Industry

Technology Awards

- 2023: Won the Sasaki Award from the Japan Technical Association of the Pulp and Paper Industry

- 2022: Invention Encouragement Award presented by the Invention Association of the Kanto Region

- 2019: Won Agency of Natural Resources and Energy Director-General's Award in the 2019 Energy Conservation Grand

Testimonials

1) +3% productivity

2) -6% Gas Consumption

3) 108 T/Year CO2 Emissions Savings

We can recommend Kurita Europe as a reliable partner for all questions regarding water treatment as well as Kurita Dropwise Technology to increase the efficiency of the paper production process.

Steam consumption per ton of paper was reduced by an average of 7% across all grammages, with some reaching up to 10%. This resulted in significant decreases in fuel costs and CO2 emissions.

Case Studies

Improved operation in corrugated board manufacturing

Energy Savings with Kurita Dropwise Technology

A textile mill deeply drops its energy consumption

Related Solutions

S.sensing™ VP

Kurita’s S.sensing™ VP concept smartly monitors water treatment systems, offers insights, identifies areas for improvement, and helps reduce energy use to achieve sustainability goals.

Kurita Connect 360

Kurita’s digital customer platform for global water management enhances your system performance by providing continuous intelligent recommendations and monitoring of your water treatment applications.